Welcome to HongChang Aluminum CO., LTD.

Visit

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Welcome to HongChang Aluminum CO., LTD.

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Keyword,Search Intentbest thermal CTP plates for long run offset printing,Commercialwholesale price per square meter CTP plate for offset,TransactionalUV CTP plates vs thermal CTP plates comparison for offset,Investigational830nm thermal CTP plate manufac

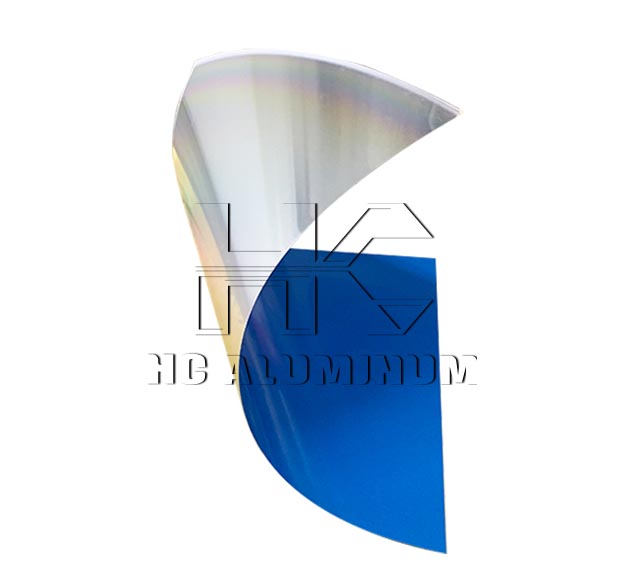

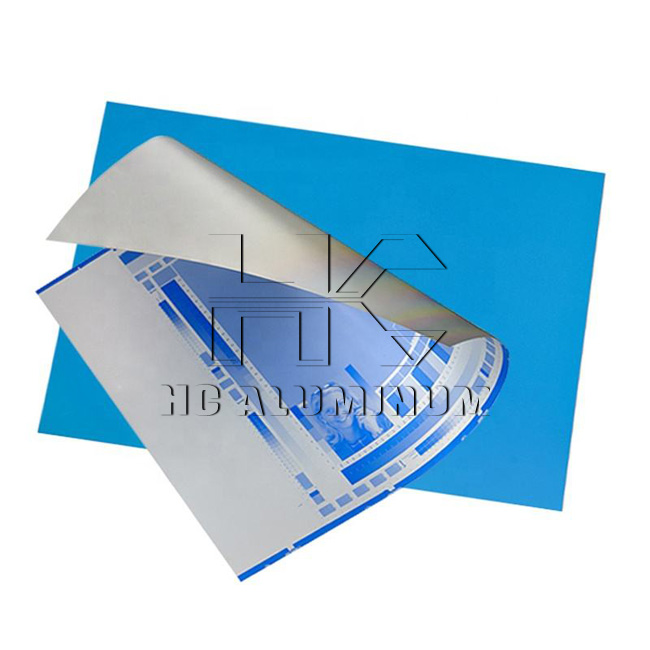

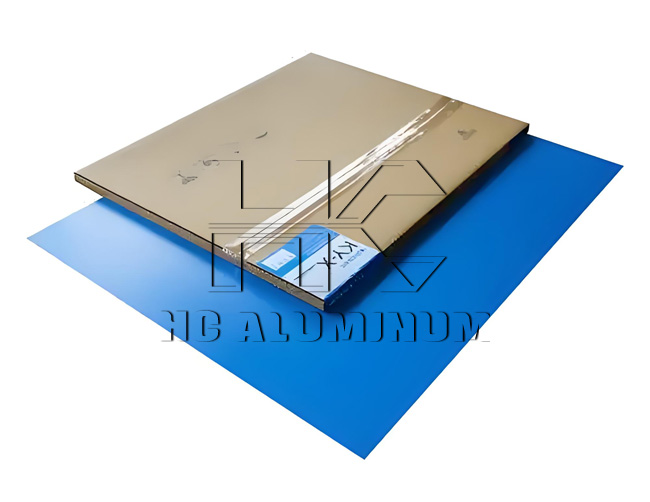

Blue Thermal CTP Printing Plates designed for 830nm thermal imaging deliver high resolution, stable dot reproduction, and long run length. Compatible with mainstream CTP systems, suitable for commercial, packaging, and newspaper printing applications.

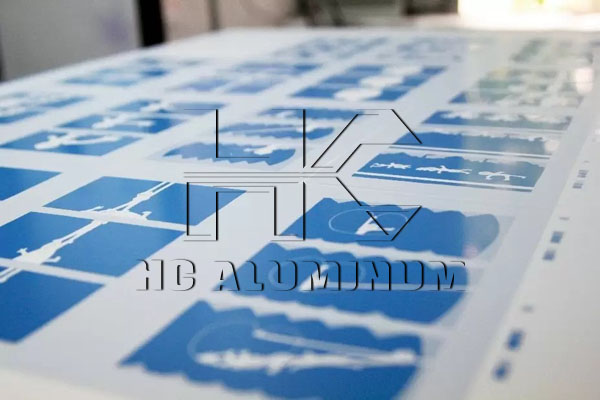

CTP plates are mainly divided into five categories: thermal plates, violet laser plates, silver salt plates, UV-CTP plates, and the emerging free-processing plates. They are widely used in printing newspapers, magazines, etc.

The mainstream offset printing plates are divided into PS plates and CTP plates. Both have their own characteristics. CTP plate making is gradually becoming the industry's first choice with its many advantages.

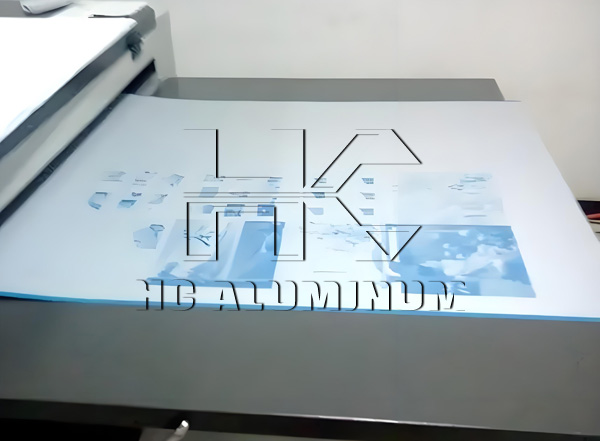

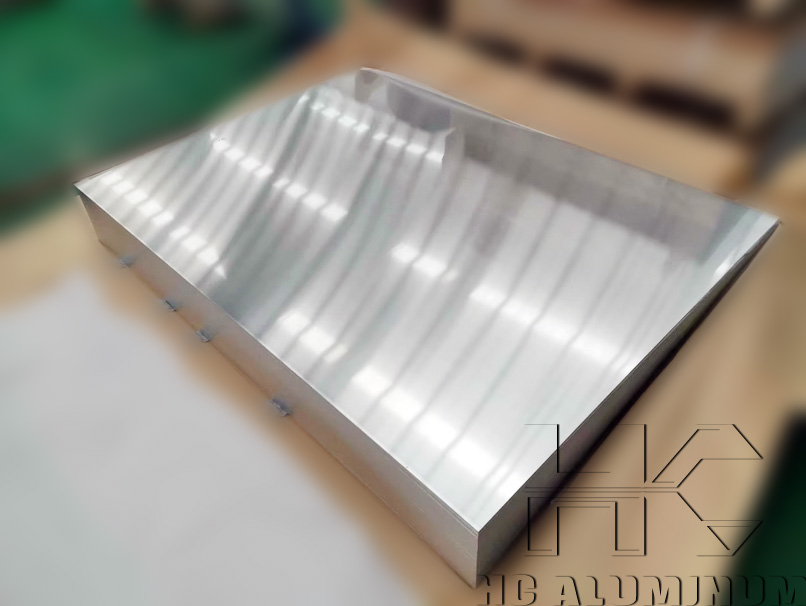

CTP plate is a printing plate substrate specially used in CTP platemaking process. It is made of high-quality aluminum substrate and its surface has a complex grain structure and a dense oxide layer.

1350mm CTP plates, featuring high stability, durability, and excellent photosensitivity, are widely used in high-end printing applications. Available in a variety of custom sizes, they help printing companies improve efficiency and quality.

Blue thermal CTP printing plate is the core material in modern printing technology and is widely used in various types of high-precision and large-scale printing production. This printing plate combine

Hongchang Aluminum currently produces four main types of CTP plates, including heat-sensitive, silver salt, photopolymerization and processing-free types.

Thermal CTP plates use an infrared thermal laser around 830nm to create images directly on aluminum-coated plates, eliminating the need for traditional film transfer processes.

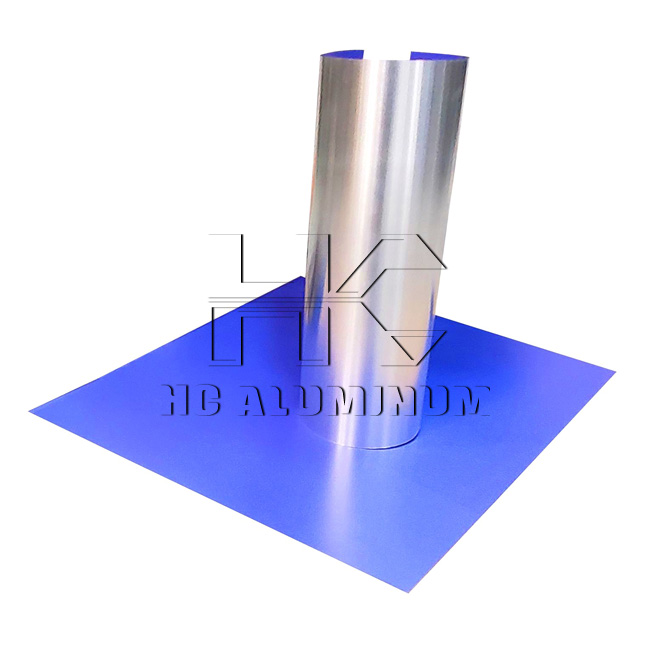

Processless thermal CTP plates use 830 nm thermal imaging technology and require no chemical development, offering high plate-making efficiency and excellent stability, making them ideal for high-volume commercial and packaging printing applications.

CTP plates primarily use aluminum plates, which not only improves printing efficiency but also reduces plate-making costs.

CTP plate is a printing plate that is directly exposed and imaged by a computer platemaking system, eliminating the complex film process in traditional platemaking and greatly improving platemaking efficiency and printing accuracy.

0.3mm thick CTP plates are especially suitable for medium to large-sized printing equipment and scenarios with high requirements for printing accuracy and durability.

Thermal CTP plates have higher exposure accuracy, more stable imaging characteristics and wider environmental adaptability, and are the preferred plate material in commercial printing, newspaper printing and other fields.

With the vigorous development of the printing industry, the demand for printing plates has shown a significant growth trend. Among them, the demand for PS plates/CTP plates, which are the main printing plates, is particularly prominent. The PS version of

CTP plates of different thicknesses have different compressive strength, printing durability, stability and compatibility.

Thermal CTP plates are one of the core plate materials used with mainstream printing presses, offering high efficiency, high stability, and high resolution.

There are two main types of common CTP plates: Violet CTP and Thermal CTP.

Process-free CTP plates effectively solve the problems of hazardous waste and emissions, and reduce electricity and water consumption, allowing you to achieve "green" printing.

Hongchang's high-quality CTP aluminum substrate uses 1 series high-purity aluminum, which is flat and corrosion-resistant, ensuring high-resolution imaging and stable printing strength, and is widely used in the digital printing industry.

UV-CTP and thermal CTP are two mainstream CTP plate making methods, which are widely used in newspapers, magazines, advertisements, commercial printing, etc.