If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

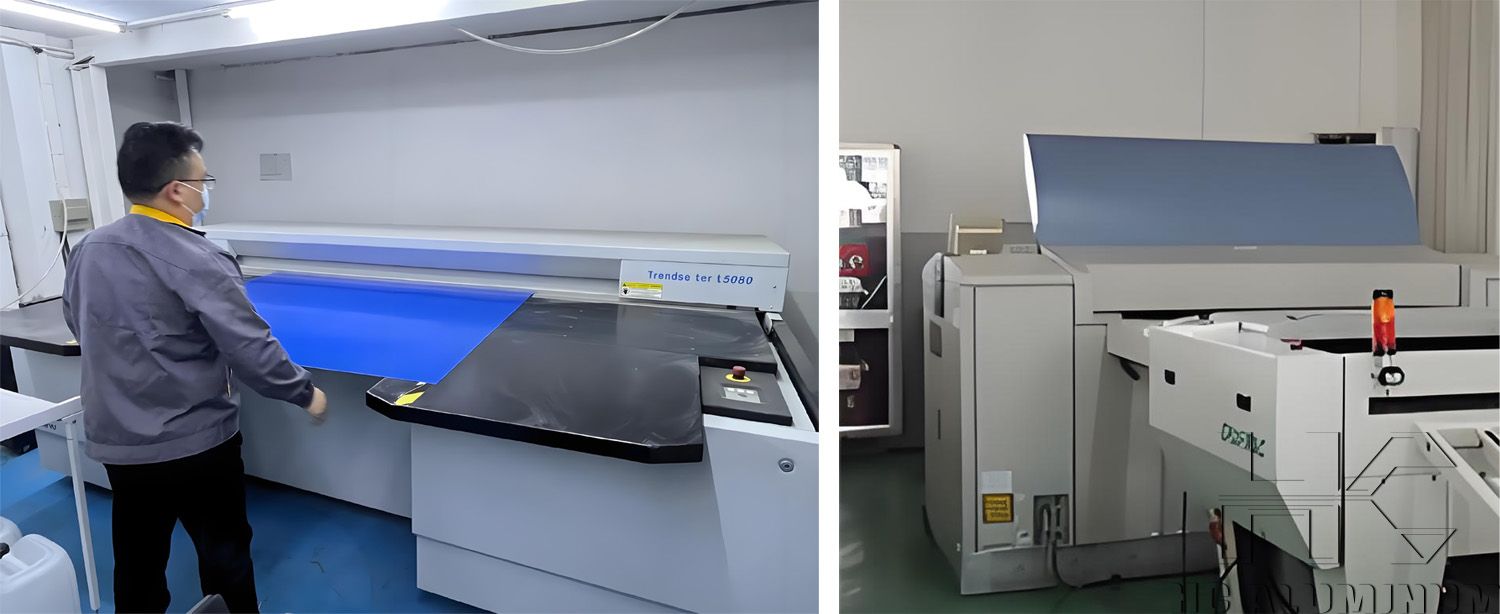

The Most Cost-Effective CTP Plates

What is a CTP Plate?

A CTP (Computer-to-Plate) plate is a printing plate imaged directly by a computer-to-plate system, eliminating the traditional film step. This greatly improves prepress efficiency and printing accuracy.

Common Types of CTP Plates

Features: Uses thermal laser imaging, insensitive to ambient light, and provides stable imaging with highly accurate dot reproduction. High-end models can even be processless, meaning they require no developing and can go directly to press.

Cost Advantage: While the unit price is slightly higher than UV plates, thermal plates offer extremely stable imaging with very low waste. Their reduced chemical use and lower maintenance costs result in lower overall operating costs. Ideal for high-quality, long-run jobs and environmentally conscious printing.

Applications: High-end commercial printing, long-run jobs, high-precision color printing, packaging printing.

2. UV-CTP Plate

Features: Uses ultraviolet laser imaging and is sensitive to ambient light. The technology is mature, and prices are highly competitive, making them generally cheaper than thermal plates.

Cost Advantage: Low purchase price is its biggest selling point. Suitable for businesses with limited budgets or those handling short-run jobs with less demanding quality requirements.

Applications: Short-run printing, newspaper printing, and general print jobs with moderate color accuracy requirements.

Key Performance Features of CTP Plates

Excellent developability: Quick press setup, low waste rate, reduced labor cost.

High durability: Standard plates can reach up to 50,000 impressions, while premium plates can achieve up to 200,000 impressions.

Strong compatibility: Works with mainstream CTP equipment and processors.

Eco-friendly: Processless plates reduce chemical usage, supporting sustainable and green printing.

Applications of CTP Plates

Newspaper Printing Plants: Require fast plate-making and high-volume output.

Commercial Printers: Brochures, magazines, catalogs, advertising flyers.

Packaging Printers: High-quality printing for cartons, labels, and packaging boxes.

CTP Plate Sizes

There is no universal standard for CTP plate sizes. Dimensions vary depending on press type, job requirements, and final product size.

Common thicknesses: 0.15mm, 0.20mm, 0.25mm, 0.28mm, 0.30mm, 0.40mm

Typical sizes (mm): 510 × 400, 650 × 550, 745 × 605, 920 × 760, 1050 × 820, 1160 × 940, 1325 × 1650

Formats:

Small format: ~500 × 400mm, suitable for flyers and booklets.

Medium format: 745 × 605mm, widely used for commercial printing.

Large format: For advertising and packaging; can reach over 1600mm.

Custom sizes are also available depending on machine and job specifications.

How to Find the Most Cost-Effective CTP Plates?

Choose reliable manufacturers & direct supply: Direct factory supply helps avoid middleman markups.

Match plate to job requirements: Select standard or high-durability plates based on run length, avoiding unnecessary cost from over-specification.

Check after-sales service & supply stability: Large-scale production requires consistent supply and technical support to prevent downtime losses.