If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

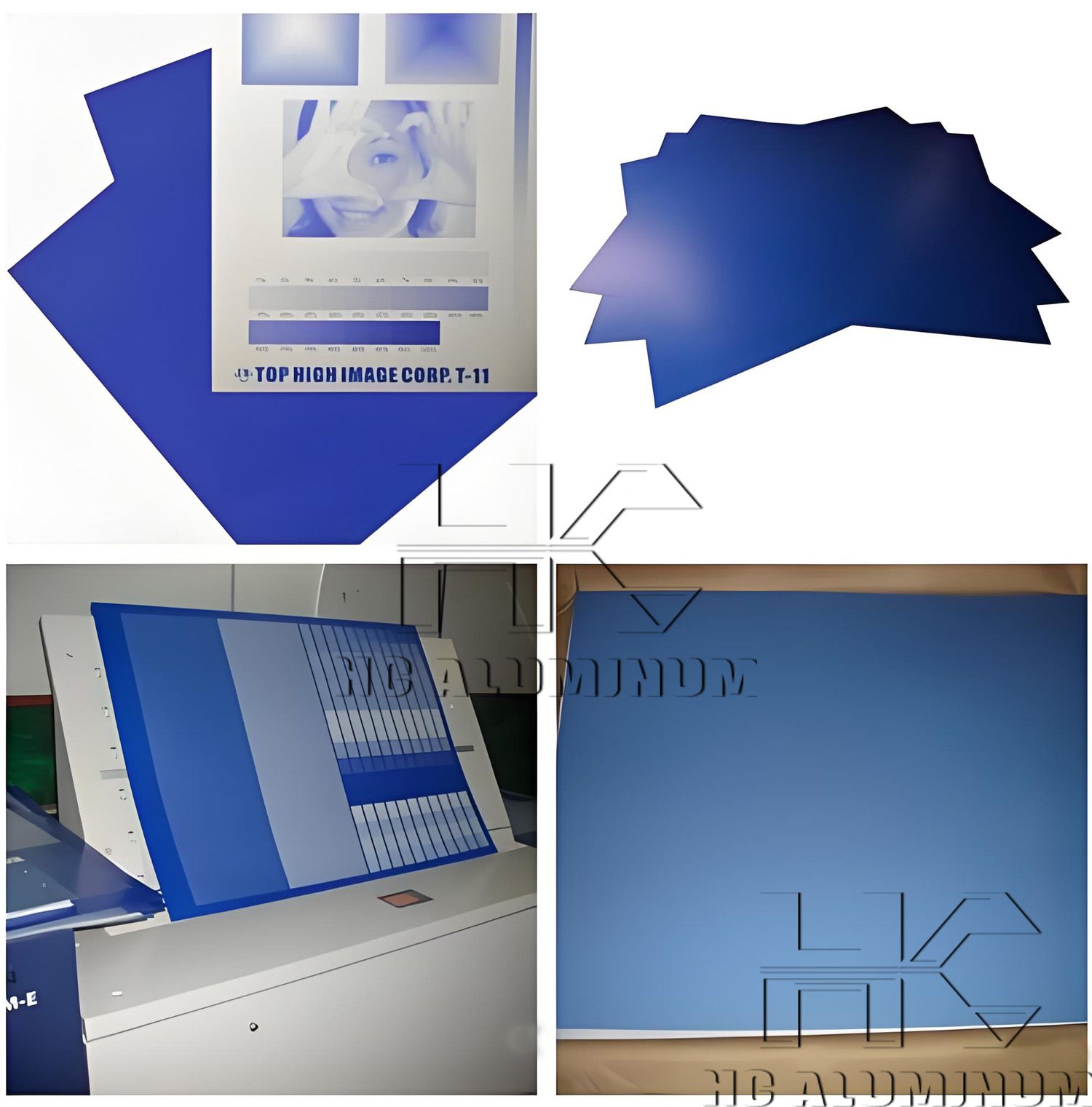

CTP Printing Plate-Making Process

CTP technology, short for Computer To Plate, is a plate-making process that directly transfers digital content or pages from a Color Electronic Pre-press System or a Desktop Publishing (DTP) system onto printing plates. Since its emergence in the 1980s, CTP has revolutionized traditional printing workflows. In developed countries such as those in Europe, the U.S., and Japan, the shift to CTP plates has already become a growing trend.

Advantages of CTP Technology:

Environmentally Friendly: Eliminates the need for photographic films and their chemical processing, reducing environmental pollution.

High Production Efficiency: Avoids steps such as film development, retouching, and plate exposure, saving significant time and workspace.

Simplified Equipment: No need for darkrooms or film processing equipment, streamlining the production line.

Cost Reduction: Direct transition from digital content to printing plates lowers production costs and increases economic efficiency.

Enhanced Image Quality: Delivers superior image transfer, greatly improving the visual quality of printed materials.

At HONGCHANG Aluminum, we currently produce four main types of CTP plates: thermal, silver halide, photopolymer, and processless plates. Each type offers unique advantages and application scenarios, providing flexible solutions for printing businesses.

The key equipment in the CTP printing platemaking process includes computers, CTP equipment, and printing presses. Computers process graphic information, CTP equipment exposes the printing plate, and printing presses transfer ink to the substrate. The performance of these devices directly impacts the efficiency and quality of the entire process.

How the CTP Plate-Making Process Works

The core principle of the CTP process is the direct output of image and text data from a computer to the printing plate. It generally includes the following steps:

Digital Prepress: Graphic and textual content is processed using professional design software, generating files suitable for plate output.

Plate Exposure via CTP Device: The processed files are exposed onto the plate using the CTP machine.

Plate Processing: The exposed plate undergoes development, fixation, and rinsing to remove unwanted areas and retain the desired image.

Plate Drying: After processing, the plate is dried to prepare for the next stage—printing.

Why Choose Our CTP Plate-Making Services?

Advanced Equipment: Equipped with world-class CTP machines from Heidelberg, Kodak, Fuji, SCREEN, and more.

High-Quality Plates: Supports a variety of thermal and violet laser plates to meet diverse printing needs.

Skilled Technical Team: Years of experience ensure precision and consistency in every plate.

Fast Turnaround: Urgent orders can be completed the same day, with remote file submission and proofing available.

Eco-Friendly Practices: Promoting processless plate technology to support sustainable and green printing.