If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

Offset Printing Plates for Newspaper Printing

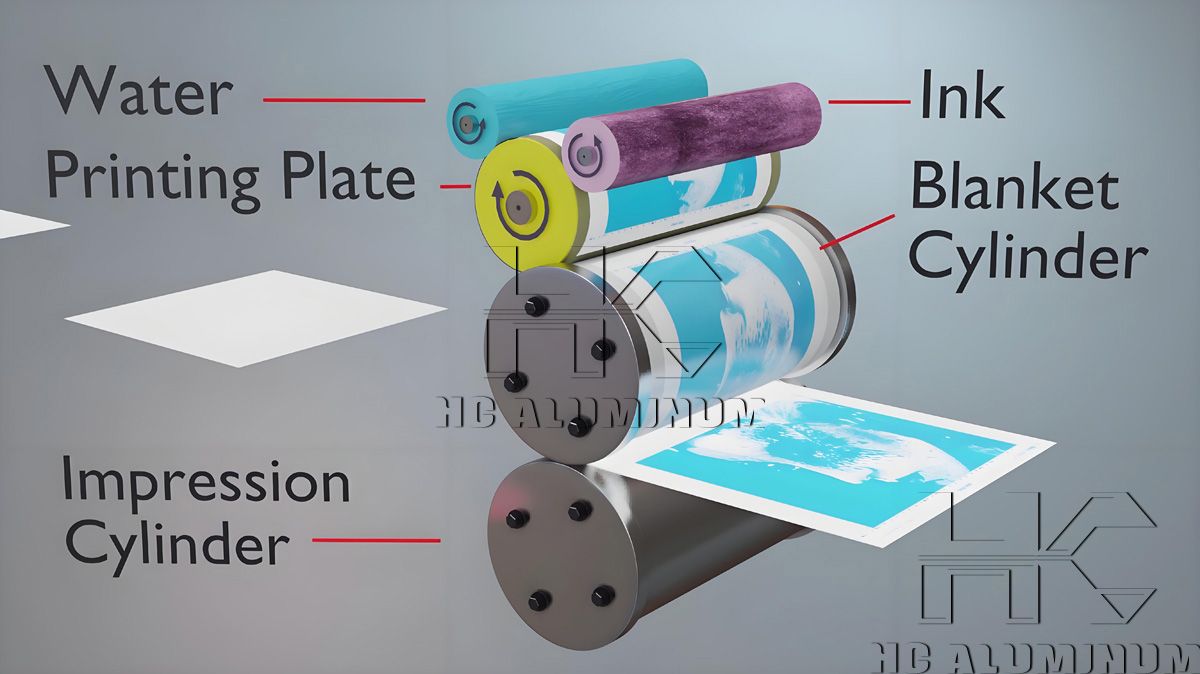

Offset printing, a major leap forward following Johannes Gutenberg’s invention of the first printing press, applied lithographic printing technology, replacing metal plates with limestone to reproduce artworks, thus enabling low-cost printing of written works.

As newspaper printing gradually declines and news providers shift toward digital platforms, aluminum plate printing has become a symbol of traditional offset printing technology. Offset plates are made from high-purity aluminum sheets (1050, 1060, 1070 alloys) coated with a photosensitive material. A film of the desired image is placed on the photosensitive layer, and after exposure, the coating hardens in the image areas. Modern offset printing requires four separate plates for each sheet of paper, each representing one of the four process colors: cyan, magenta, yellow, and black (CMYK).

Today’s newspaper printing predominantly uses aluminum-based plates (such as PS plates and CTP plates) processed through automatic plate processors, replacing the early lead-type and film plate-making processes. Aluminum substrates are lightweight and have high printing durability, making them well-suited for high-speed web press printing requirements.

In the newspaper industry, offset printing is the mainstream method due to its high speed, consistent print quality, and suitability for large-volume production.

Main Types of Offset Printing Plates Used in Newspaper Printing

PS Plate (Pre-sensitized Plate)

The PS plate is the earliest plate type to be widely adopted in offset printing and has long been the workhorse of traditional newspaper production. It consists of an aluminum base pre-coated with a photosensitive layer. Through exposure and development, the image is formed on the plate surface.CTP Plate (Computer-to-Plate)

CTP plates represent the modern standard for newspaper printing. They eliminate the traditional film-making step, with image data transferred directly from the computer to the plate-making machine. A laser scans and exposes the photosensitive layer on the aluminum substrate to form the image.

Why Do Newspapers Prefer Offset Printing Plates?

1. Suitable for High-Speed, Large-Volume Production

Newspaper presses often need to print tens of thousands or even hundreds of thousands of copies within a few hours. Offset plates have high durability (often exceeding 100,000 impressions) and can maintain consistent image quality during high-speed operation without noticeable wear from prolonged contact.

2. Stable Print Quality

The photosensitive coating and aluminum substrate of offset plates are precisely processed to achieve excellent ink-water balance, ensuring sharp text and clear image gradations. This is especially important for the fine type, thin lines, and news photographs commonly found in newspapers.

3. Fast Plate-Making, Flexible Response

Whether using traditional PS plates or modern CTP plates, offset plates enable rapid plate-making. In the fast-paced newspaper industry, where page layouts change frequently, the quick imaging capability of offset plates allows seamless workflow from layout to printing, reducing the publishing cycle.

4. Significant Cost Advantages

Compared to digital printing, offset printing offers lower per-sheet costs for large print runs. The mass production cost of offset plates is manageable, and plates can be reused to some extent, further reducing expenses — a key factor for large daily newspapers.

5. High Compatibility and Versatility

Offset plates are available in various types (PS plates, thermal CTP plates, process-free plates) and are compatible with different brands and models of newspaper printing presses. Their standardized material and thickness specifications make centralized purchasing and inventory management easier for printing houses.

6. Improved Environmental Sustainability

In recent years, the adoption of process-free plates and low-chemical plates has significantly reduced chemical waste discharge and energy consumption in newspaper printing. This trend helps offset plates maintain competitiveness in the era of green printing.

Applications of Offset Printing Plates

Books and Newspapers: Widely used for textbooks, catalogs, manuals, and other printed reading materials.

Color Printing: Magazines, brochures, promotional leaflets.

Food Packaging: Printing on food boxes, bags, and labels.

Pharmaceutical Packaging: Printing medicine instructions and outer packaging labels.