If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

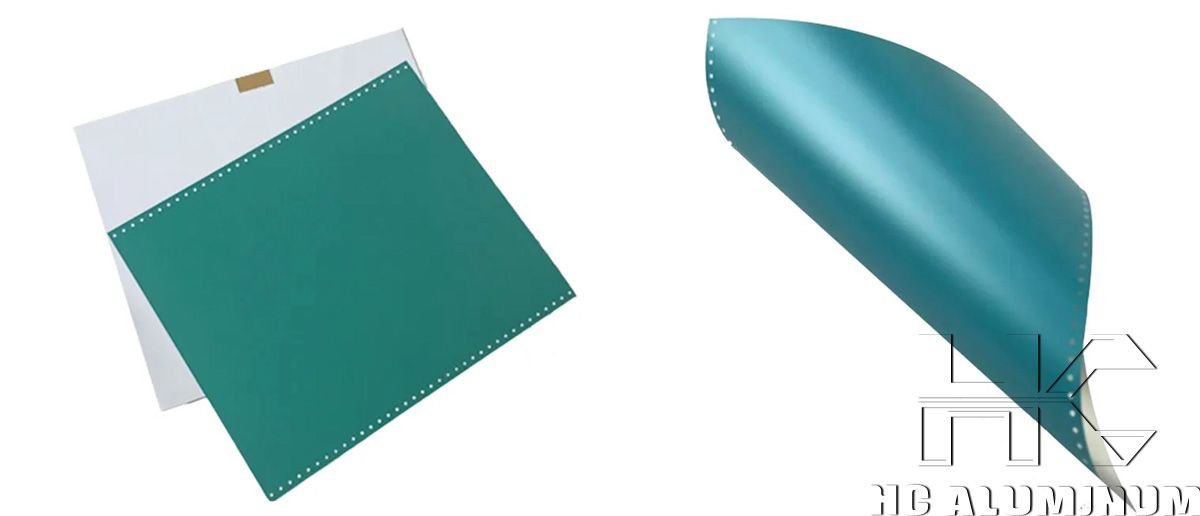

PS Printing Plate for Label Printing

As a traditional and essential material in lithographic printing, the PS plate plays a vital role in the label printing industry.

A PS plate is a pre-coated photosensitive lithographic printing plate made from aluminum (typically 1050, 1060, or 1070 alloy) as the base material. The surface is coated with a photosensitive layer (usually a photopolymer), making it widely used across various printing processes. PS plates feature high resolution, excellent wear resistance, and precise image reproduction, making them one of the key materials in modern label production.

Technical Principle

The core of a PS printing plate is the pre-coated photosensitive plate. A photosensitive coating, sensitive to ultraviolet light, is applied to the surface of a 1050/1060 aluminum substrate. The production process begins with an electronic file of the design artwork, which is then used to create film via an output device or directly employs digital plate-making technology. During exposure, the photosensitive areas of the plate undergo a chemical reaction, becoming soluble in the developer. After development, clear image and non-image areas are formed on the plate. The image areas are oleophilic, while the non-image areas are hydrophilic. This ensures that during printing, the ink adheres only to the image areas, achieving precise printing.

Advantages of PS Printing Plates in Label Printing

1. High Image Precision

PS plates reproduce fine lines, micro-text, and gradient tones, ensuring clear and visually appealing labels.

2. High Production Efficiency

Photosensitive PS plates support rapid plate-making and automated exposure, significantly reducing production time and improving label printing efficiency.

3. Compatibility with Multiple Materials

Whether printing on paper, PVC, PET, or thermal labels, PS plates deliver stable printing performance and accurate color reproduction.

4. Strong Durability

High-quality PS plates maintain image clarity even during long-run, high-speed printing-reducing the frequency of plate replacement and lowering production costs.

5. Cost-Effectiveness

Compared with other plate materials, PS plates offer lower production costs and controlled per-label costs during mass printing.

PS Printing Plate Sizes and Applications

| Thickness Range | Size Range | Suitable Label Type |

| 0.3-0.5 mm | 500 × 650 mm | Paper labels, small-batch printing |

| 0.5-0.8 mm | 600 × 800 mm | PVC/PET labels, roll labels |

| 0.8-1.2 mm | 700 × 1000 mm | Thermal/self-adhesive labels, large-scale printing |

Label Printing Process Using PS Plates

1. Design Preparation:

Create the label layout using professional software, including text, graphics, and barcodes, while considering color mode, dimensions, and bleed settings.

2. Film Output or Digital Plate-Making:

Traditional methods use film negatives, while modern workflows use computer-to-plate (CTP) systems to transfer artwork directly onto PS plates.

3. Exposure and Development:

The exposed plate is developed in a chemical solution that removes unexposed photosensitive coating, creating distinct image and non-image zones.

4. Printing:

Mount the developed plate onto the offset press. Using the water-ink balance principle, ink transfers to the label substrate only where required. Ink volume, pressure, and registration accuracy are carefully controlled.

5. Post-Processing:

After printing, labels can be laminated, die-cut, hot-stamped, or slit to achieve specific finishes and functionalities.

6. Inspection and Packaging:

Finished labels are inspected for quality, defective items are removed, and qualified products are packed for shipment.

FAQ

Q1: What types of labels are suitable for PS printing plates?

A1: PS plates are suitable for paper, PVC, PET, self-adhesive, and thermal labels, covering a wide range of applications.

Q2: Can PS plates support high-precision printing?

A2: Yes. High-resolution PS plates can reproduce fine text, thin lines, and gradient details with exceptional accuracy and clarity.

Q3: How durable are PS printing plates?

A3: Premium PS plates are highly wear-resistant, maintaining image quality during high-speed and long-duration printing, minimizing replacement frequency.

Q4: Can sizes and thicknesses be customized?

A4: Yes. Manufacturers can customize plate size and thickness based on printing machine models and label dimensions to maximize productivity and print quality.

Q5: Are PS printing plates environmentally friendly?

A5: Yes. PS plates meet food-grade safety standards and contain no heavy metals or harmful chemicals, making them ideal for food, pharmaceutical, and daily product label printing.