Welcome to HongChang Aluminum CO., LTD.

Visit

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Welcome to HongChang Aluminum CO., LTD.

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

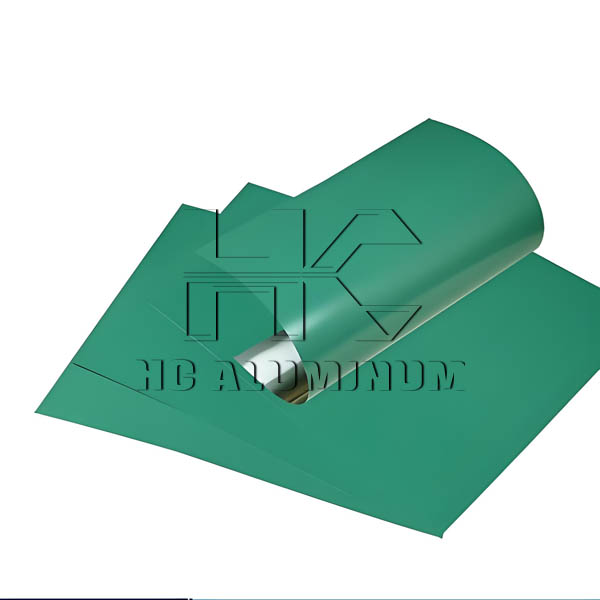

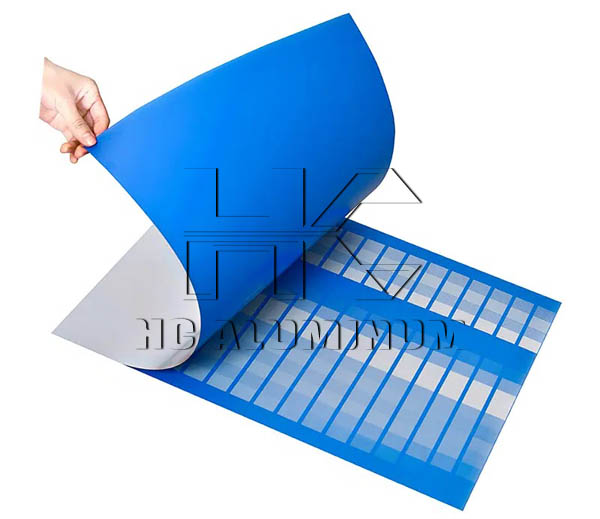

Processless thermal CTP plate is a type of plate material specially designed for computer-to-plate (CTP) technology, featuring significant characteristics such as environmental protection, high efficiency, and high quality.

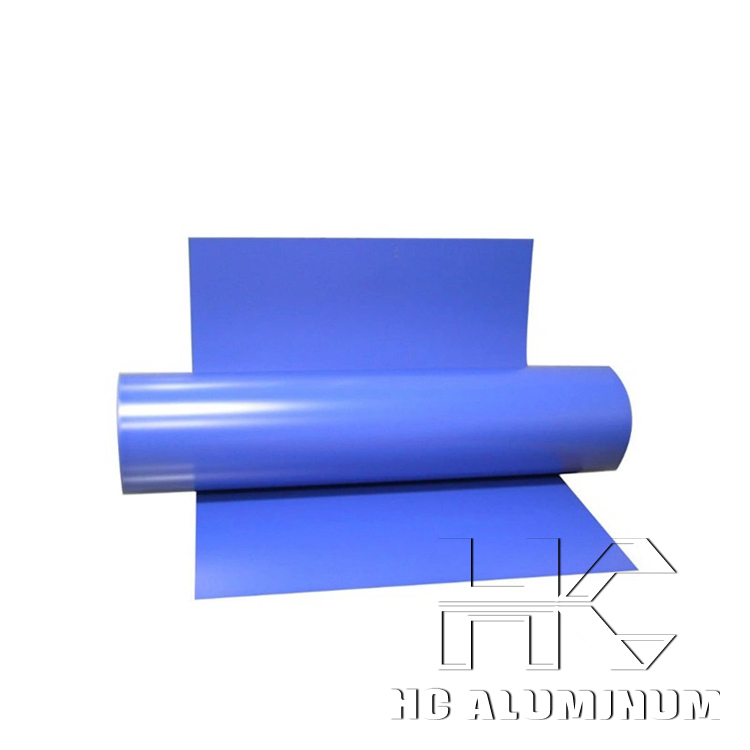

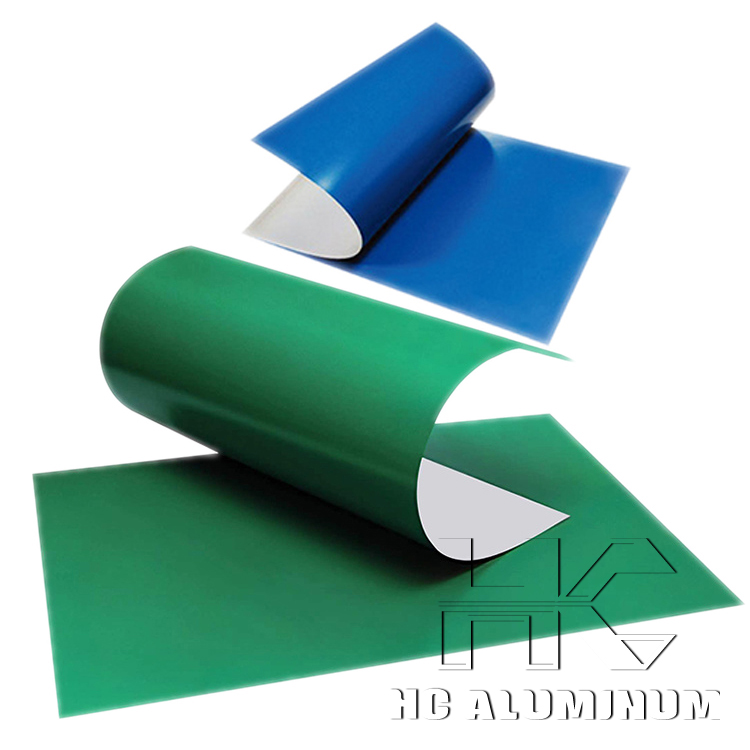

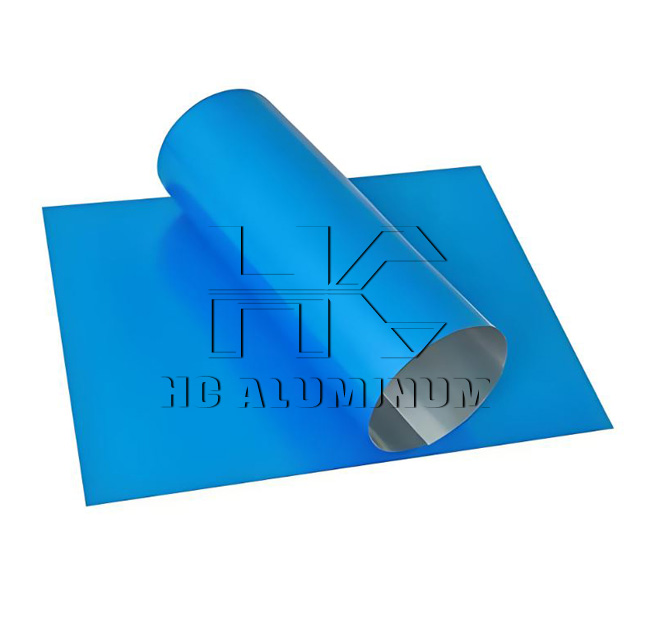

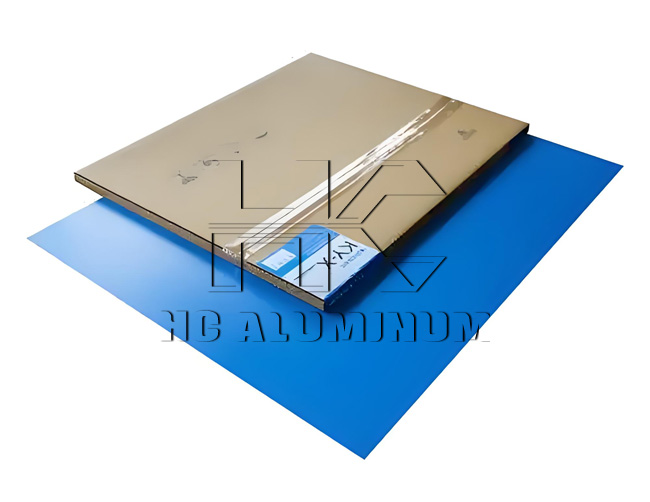

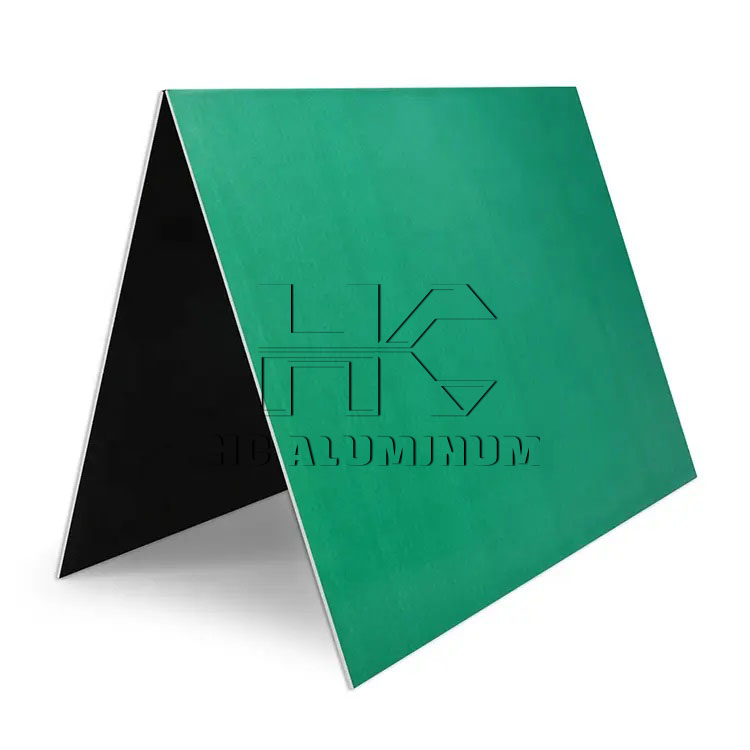

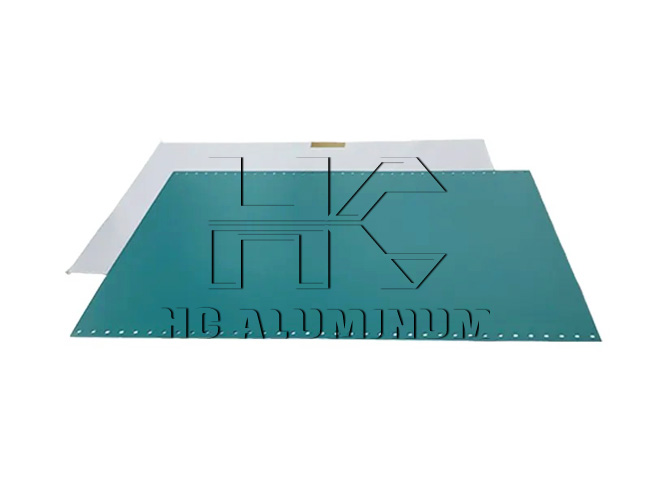

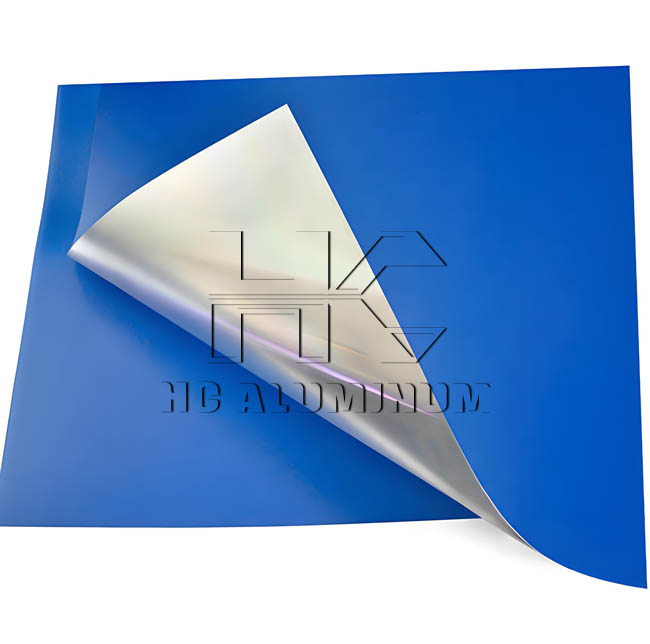

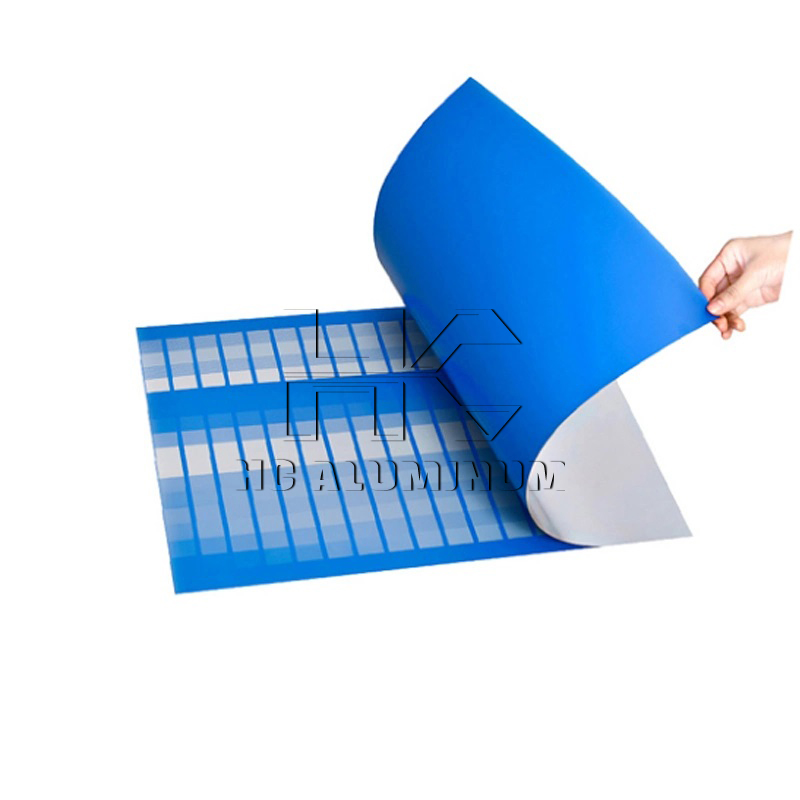

Positive offset PS plates have excellent flatness, ink receptivity and hydrophilicity, high strength and light weight, good thermal conductivity and electrical conductivity, environmental protection and recyclability, strong adaptability, and ease of hand

The mainstream offset printing plates are divided into PS plates and CTP plates. Both have their own characteristics. CTP plate making is gradually becoming the industry's first choice with its many advantages.

The aluminum substrate offset printing PS plate is a new type of printing material that has become an essential component in the offset printing industry due to its exceptional printing performance, long-lasting durability, and environmental benefits.

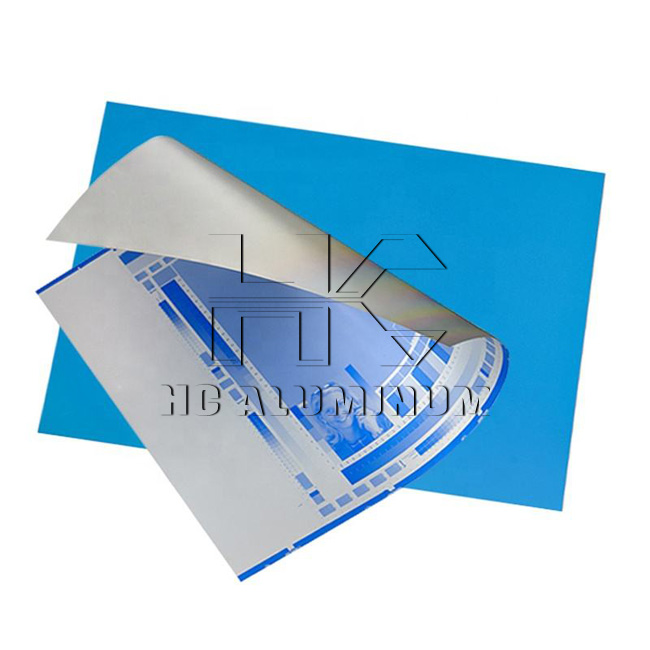

CTCP (Computer to Conventional Plate) printing plate refers to the use of traditional PS plates with direct digital imaging, forming a new generation of UV-CTP plates.

The alloy types of aluminum plates for printing bases usually include 1050, 1060, 1070, 1100, etc.

PS plate aluminum plate base usually uses high-purity aluminum alloy, which has good corrosion resistance and thermal conductivity. Commonly used aluminum alloys include 1050, 1060 and other series.

Aluminum PS plates are the core consumables of offset printing presses. The base material is primarily 1050, 1060, or 1070 aluminum alloy. The surface is electrolytically oxidized to create a grain structure and then coated with a photosensitive resin.

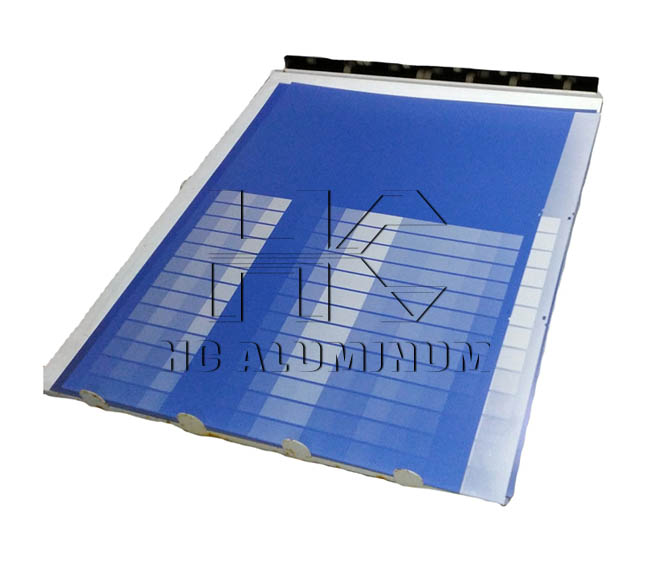

Thermal CTP plates use an infrared thermal laser around 830nm to create images directly on aluminum-coated plates, eliminating the need for traditional film transfer processes.

UV-CTP and thermal CTP are two mainstream CTP plate making methods, which are widely used in newspapers, magazines, advertisements, commercial printing, etc.

In the field of newspaper printing, offset printing technology has become mainstream due to its fast speed, stable printing quality and adaptability to large-scale printing.

CTCP refers to a computer-to-plate imaging process using traditional PS plates (Presensitized Plates) or, in some contexts, CTP plates.

PS plate is a printing plate commonly used in lithography. It is made by coating a layer of photosensitive material on an aluminum plate substrate.

CTP plates of different thicknesses have different compressive strength, printing durability, stability and compatibility.

There are two main types of common CTP plates: Violet CTP and Thermal CTP.

A 0.15mm thick aluminum PS plate is a lightweight printing plate specification, usually made of 1050, 1060 or 1070 series aluminum alloys with a purity of 99.3% or higher.

CTP plates primarily use aluminum plates, which not only improves printing efficiency but also reduces plate-making costs.

Hongchang Aluminum focuses on the research and development and production of offset printing plates. Its products cover offset printing plates, thermal CTP plates, and raw material aluminum substrates, and are widely used in books, packaging and other fie

The aluminum alloys commonly used in printing plates include 1050, 1060, and 1070 series pure aluminum, which have aluminum contents above 99.5%.

The aluminum plates used in printing houses are mainly PS plate aluminum plate base and CTP plate aluminum plate base, generally made of 1050, 1060, 1070 and other aluminum alloy materials.

Printed aluminum plate usually uses aluminum alloy as the substrate, commonly used 1050 aluminum alloy, 1060 aluminum alloy, 1070 aluminum alloy, etc.

The core advantages of 830 nm thermal CTP plates lie in their operational stability and the convenience of working in a brightly lit environment.

PS plates are offset printing plates made of aluminum plates (1050/1060/1070) as the base material and pre-coated with a photosensitive layer. They are widely used in various printing processes.

The CTCP plate is mainly composed of a high-quality aluminum substrate and a photosensitive coating.

1-Series photopolymer plate aluminum substrates are made from 1050, 1050A, 1060, and 1070 aluminum sheets as the supporting material for photopolymer plates (such as PS plates and CTP plates).

PS plate is used in various printing fields, such as books, magazines, newspapers, packaging, advertising, etc. Its high-quality printing effect and stable performance make it one of the important materials in the printing industry.

CTCP uses traditional PS plates and ultraviolet light, while CTP uses special plates and lasers.

CTCP (Computer to Conventional Plate) is a hybrid printing technology that combines the advantages of digital and traditional offset printing.

1 series aluminum alloy plates are commonly used for PS plate substrate/CTP plate substrate, with advantages such as high printing quality, strong printing durability, environmental friendliness, cleanliness and hygiene, and low cost.

The CTCP plate produced by HONGCHANG Aluminum is renowned for its high resolution, superior quality, excellent compatibility, and cost-effectiveness.

Aluminum coils for CTP/PS base plates are mostly made of high-purity aluminum alloys, such as 1050, 1060, 1100, etc. The aluminum content of these alloys is ≥99.50%, ≥99.60% and ≥99.00%, respectively. They have the advantages of high purity, low density,

A PS plate (Pre-sensitized Plate) is a pre-coated photosensitive plate usually composed of an aluminum substrate and a photosensitive coating.