If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

Positive PS Plate for Newspaper Printing

The Positive PS Plate is a pre-sensitized aluminum printing plate designed specifically for high-speed newspaper web printing. Featuring a positive-working photosensitive coating, it is suitable for UV exposure and produces excellent imaging results after development. With fast plate-making speed, high resolution, and strong run length, it has become the mainstream prepress plate material used by newspaper publishers and printing groups worldwide.

What is a Positive PS Plate?

PS Plate: A PS (Pre-Sensitized) plate is a commonly used plate in offset printing, consisting of a photosensitive coating on a grained aluminum substrate.

Positive Plate: In a positive-working plate, image areas on the plate correspond to image areas on the original artwork. The exposed areas are removed during development, leaving the image to accept ink.

Working Principle

In the production of positive PS plates, digital image files are directly transferred onto the plate via a CTP (Computer-to-Plate) system using thermal or UV laser exposure. After exposure, the image areas remain on the plate while non-image areas are removed during development, revealing hydrophilic aluminum. During printing, the image areas attract ink, which is transferred to paper to reproduce the desired design.

Key Features for Newspaper Printing

1.High Sensitivity: Enables fast imaging, crucial for time-sensitive newspaper production.

2.Fast Plate-Making: Compatible with both traditional exposure and CTP systems, optimized for rapid prepress workflows.

3.Excellent Print Adaptability: Stable performance on high-speed web offset presses.

4.Moderate Run Length: Ideal for medium- to large-volume print jobs; suitable for daily newspaper circulation.

5.Cost-Effective: Designed with affordability in mind, supporting the tight margins in newspaper printing.

6.Eco-Friendly: Aluminum substrate is 100% recyclable; lightweight design (e.g., 0.15mm) reduces shipping emissions.

Product Parameters

| Model | PS |

| Plate Type | Positive PS Plate |

Application | commercial and newspaper printing |

Substrate | Electro chemically Grained and Anodized lithographic Aluminum |

Gauge | 0.15, 0.20, 0.25, 0.30, 0.40(mm) |

Maximum short grain width | Maximum width 1280 mm |

Power of light | 3000 - 5000 w |

Length of Run | Unbaked: 50000 to 100,000 impressions Baked: Over 100,000 impressions |

Processor | All brands or Manual |

Aluminum | |

Developing time | 20-30 sec |

Spectral Sensitivity | 320 - 405 nm |

Resolution | 2-98% @ 200LPI |

Image Color | Green / Blue |

Developer | Any positive plate developer or our own developer |

Processing temperature | 20-25℃ |

Processing Speed | 0.80 - 1.20 m/min |

safelight | Handle under yellow safe light(UV free) |

Shelf life | 12 months under recommended storage conditions |

Packaging | Available in all standard formats, including bulk packaging options such as APL packaging |

Storage and handing | Stored in a cool and dry environment, away from excessive cold, heat and humidity |

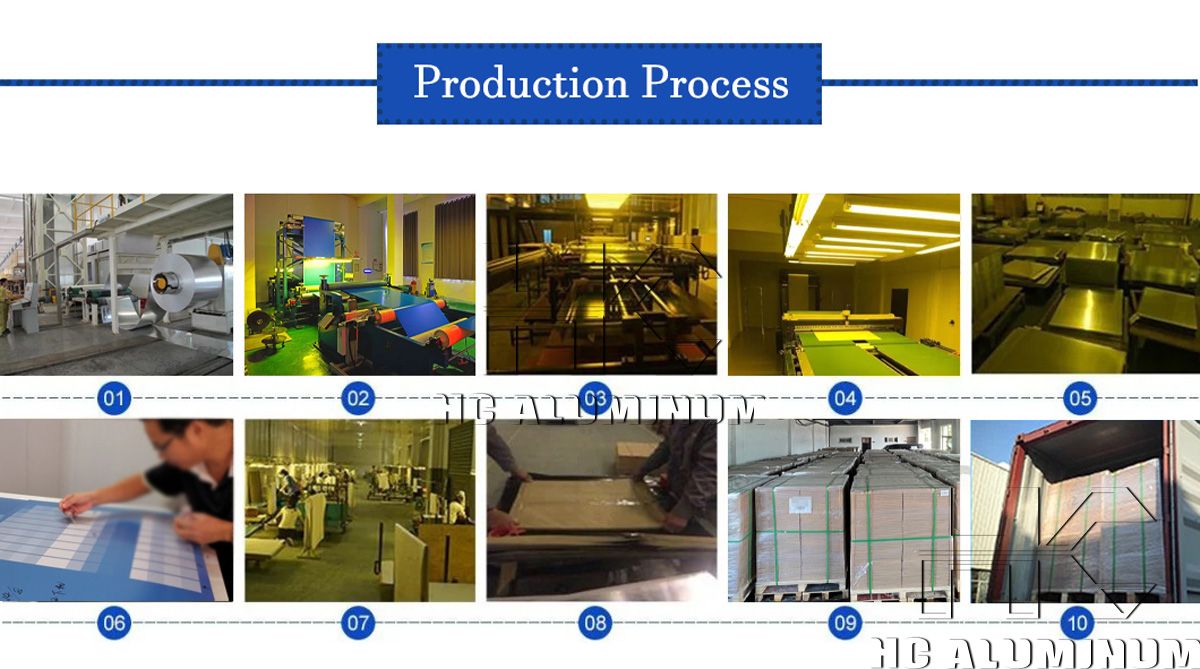

Packaging & Transportation

Standard packing: 50 sheets per carton, with wooden outer cases.

Sheets are packed with protective interleaving in cardboard boxes to prevent damage.

Storage Tips: Store in a cool, dry environment, away from direct sunlight, extreme heat, cold, or humidity.

Frequently Asked Questions (FAQ)

Q1: When can I get a quotation?

A1: We will reply to your inquiry within 24 hours. For urgent requests, you may also contact us directly via WhatsApp: +86 18703635966.

Q2: What is the typical run length of the PS plate?

A2: The standard run length is 50,000–100,000 impressions, depending on paper type, ink, and fountain solution. Higher run lengths can be achieved with baked or hard-coated versions.

Q3: What is your usual lead time?

A3: Our standard delivery time is 25–35 days after order confirmation.

Q4: Do you provide free PS plate samples?

A4: Yes, we offer free test samples (up to 12 pieces per size). However, the shipping cost is borne by the customer.

Q5: What are your payment terms?

A5: Standard terms: 30% deposit in advance, 70% balance before shipment. We also accept irrevocable L/C at sight.