If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

High-Quality 830nm Thermal CTP Plate

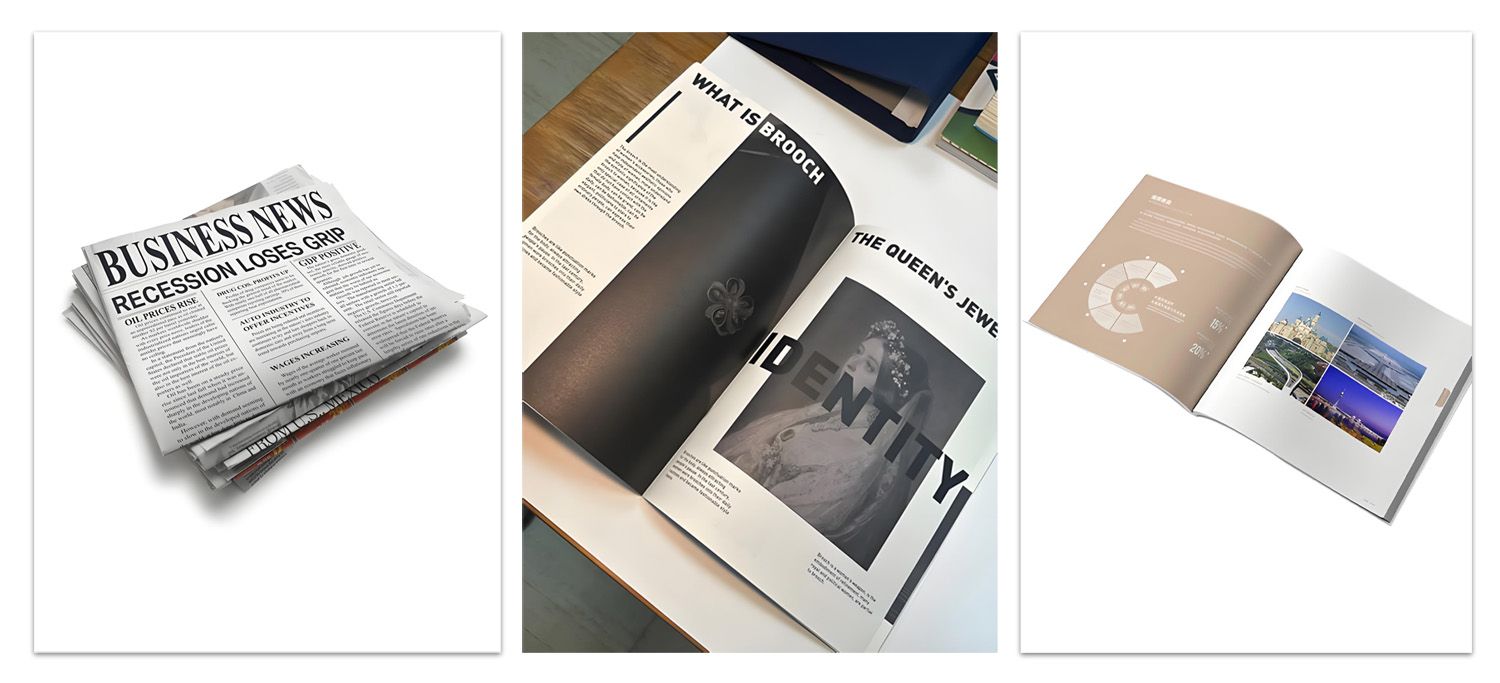

As commercial printing continues to move toward digitalization and intelligent production, CTP (Computer to Plate) technology has become the mainstream solution in offset plate making. Among all CTP solutions, the 830nm thermal CTP plate is the most widely used due to its stable imaging performance, high plate-making precision, and excellent dot reproduction.

It is extensively applied in book and magazine printing, packaging printing, commercial brochures, and high-end publishing.

Understanding the 830nm Thermal CTP Plate

An 830nm thermal CTP plate is a plate material specifically designed for computer-to-plate technology. Its imaging process relies on infrared laser exposure at a wavelength of 830 nanometers.

The plate is typically based on an aluminum substrate, coated with a thermal-sensitive layer that reacts to 830nm infrared laser energy. After laser exposure, the coating undergoes physical or chemical changes, forming clear and stable image areas. The plate is then processed through development to produce an offset printing plate ready for press.

Compared with traditional PS plates or UV-CTP plates, thermal CTP technology offers superior operational stability and true daylight handling capability.

Core Advantages of 830nm Thermal CTP Plates

1. Enhanced Printing Quality

High resolution: Rich details, sharp text, and accurate color reproduction

Sharp edges: Minimal thermal diffusion ensures clean line edges without blurring

2. Improved Production Efficiency

No photochemical exposure: Eliminates film output and chemical exposure steps

Fast imaging: Laser scanning completes plate imaging within minutes

3. Excellent Environmental Adaptability

Plates can be handled under normal white light, eliminating the need for yellow-light rooms, improving working conditions and reducing operational costs.

4. Cost Reduction

Lower waste treatment costs: No exposure-related chemical waste

Long plate life: Durable thermal layer allows tens of thousands of impressions

5. Environmentally Friendly and Sustainable

Reduced hazardous substances: No light-sensitive chemicals

Energy efficient: Thermal imaging consumes less energy than traditional exposure methods

6. Strong Equipment Compatibility

Fully compatible with mainstream 830nm thermal CTP systems, including Kodak, Heidelberg, Screen, and Agfa, offering excellent universality.

Product Specifications

| Imaging Wavelength | 830 nm |

| Resolution | 1-99% (200 lpi or higher) |

| Substrate | 1050 / 1060 / 1070 aluminum sheet |

| Standard Thickness | 0.15 mm / 0.20 mm / 0.25 mm / 0.30 mm |

| Exposure Energy | 100-160 mJ/cm² (depending on equipment) |

| Dot Reproduction | 1%-99% @ 250 lpi |

| Run Length | 100,000 impressions (unbaked) |

| Safe Light | Daylight / white light operation |

| Development Method: | Positive processing |

| Compatible Inks | Conventional offset inks, UV inks (depending on plate type) |

Why Choose the 830nm Wavelength?

Thermal CTP plates are available at different wavelengths, including 830 nm, 408 nm, and 1064 nm. Among them, 830 nm has become the industry standard due to its balanced performance.

| Feature | 830 nm | Other Wavelengths (408 nm / 1064 nm |

| Imaging depth | Moderate, suitable for most printing applications (newspapers, magazines, packaging) | 408 nm: shallow, for ultra-fine detail; 1064 nm: deeper, for thick plates |

| Thermal damage risk | Low thermal diffusion, sharp image edges | 1064 nm: higher diffusion, possible edge blur; 408 nm: lower heat, slower imaging |

| Laser cost | Mature technology, moderate cost, low maintenance | 408 nm: higher laser cost; 1064 nm: requires stronger cooling systems |

| Plate compatibility | Wide compatibility with thermal-sensitive coatings | 408 nm: limited to special high-sensitivity plates; 1064 nm: requires high heat resistance |

| Printing quality | High resolution (≥300 lpi), excellent dot reproduction | 1064 nm: slightly lower resolution; 408 nm: higher resolution but slower imaging |

Application Areas

Book, magazine, and textbook printing

Commercial brochures and promotional materials

Packaging printing (color boxes, cartons)

Label printing and high-precision graphic output

830nm Thermal CTP Plate Manufacturing Process

1. Plate Preparation

Cleaning: Removes surface dust and oil

Surface treatment: Protective or smoothing treatments applied

2. Thermal-Sensitive Coating Application

Coating methods: Spin coating, spray coating, or transfer coating

Thickness control: Adjusted to ensure uniform coating

3. Drying and Curing

Temperature: 80-120 °C

Duration: Adjusted according to coating thickness

4. Laser Imaging

Equipment: 830 nm semiconductor laser scanners (e.g., Heidelberg Speedmaster, Kodak Trendsetter, Troyka)

Parameter settings: Laser power, scanning speed, and DPI optimized per job

5. Development (Processing)

Developer: Mild alkaline solution (pH 10–11)

Process: Unexposed coating is removed, revealing the aluminum base

6. Post-Processing

Rinsing: Removes residual developer

Drying: Hot air drying or UV curing

Inspection: Magnifier or image analysis software checks line accuracy and defects

7. Mounting and Printing

Plate mounting: Installed onto the printing press cylinder

Printing: Press parameters (pressure, speed, ink volume) adjusted according to job requirements