If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

High-Sensitivity Thermal CTP Plates

As commercial printing continues to evolve toward digitalization and high-speed production, Computer-to-Plate (CTP) technology has become an indispensable part of modern printing operations. Among the wide range of CTP plate types available, high-sensitivity thermal CTP plates have emerged as the preferred solution for increasing production capacity, optimizing costs, and ensuring exceptional print quality.

What Are Thermal CTP Plates?

Thermal CTP (Thermal Computer-to-Plate) is a digital platemaking technology that uses infrared laser (typically at 830nm) to directly image onto the plate surface. Compared with violet laser CTP or traditional film-based platemaking, thermal CTP offers higher resolution, more stable development conditions, and is especially well-suited for high-precision commercial printing.

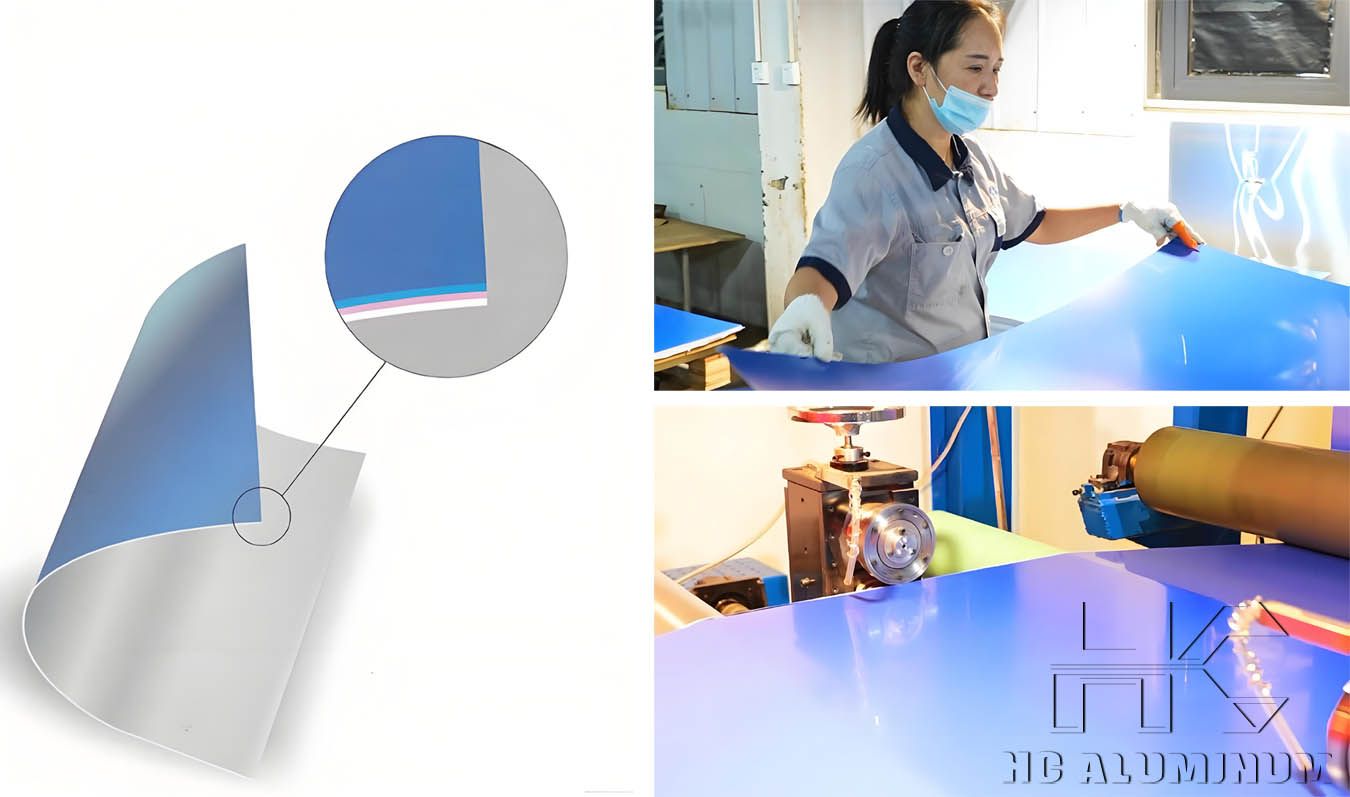

Composition of Thermal CTP Plates

High-sensitivity thermal CTP plates are photosensitive printing plates made through multi-layer precision coating and specially treated aluminum substrates. Their outstanding performance stems from a structurally integrated, functional material design.

Aluminum Substrate: Made from high-purity aluminum alloys such as 1050, 1060, or 1070, with thickness ranging from 0.15mm to 0.30mm. The aluminum undergoes electrochemical graining, anodizing, and hydrophilic treatment to enhance development speed and image resolution.

Photosensitive Layer: This layer is key to plate sensitivity. It contains light-sensitive polymers (such as diazonaphthoquinone compounds) that react chemically to 830nm infrared laser exposure. These reactions form hydrophilic and hydrophobic image areas, enabling faster exposure times, higher platemaking efficiency, and reduced laser head wear.

Printing Layer: Composed of modified polyester (PET) or epoxy resin, designed to optimize ink absorption and transfer during the printing process.

Advantages of Thermal CTP Plates

Daylight-safe operation

High-speed imaging, fully compatible with advanced CTP equipment

Energy-efficient imaging process that extends laser head lifespan

Broad exposure latitude for greater process stability

Clean development with excellent water-washability

High durability—ideal for long-run printing

Environmentally friendly

Cost-effective solution for modern print shops

Application Areas

Commercial Printing: Ideal for high-resolution brochures, packaging, and long-run offset jobs. After thermal baking, the plate can support up to 1,000,000 impressions.

Newspaper Printing: Processless thermal plates reduce platemaking time and are well-suited for fast rotary printing presses.

HONGCHANG Aluminum specializes in the production of CTP plates, PS plates, and aluminum substrates. We offer not only high-quality plates but also a complete, stable, eco-friendly, and efficient prepress solution tailored to the modern printing industry.