If you have any questions, you can directly consult our online customer service. You can visit us online via WhatsApp. We look forward to your visit.

WhatsApp:8618703635966 Online

Thermal CTP Plate - Printing Consumable

With rapid economic development and the growing demand for personalized, high-quality printed products, digital printing technology has been widely adopted globally, further driving the growth of the thermal CTP plate industry.

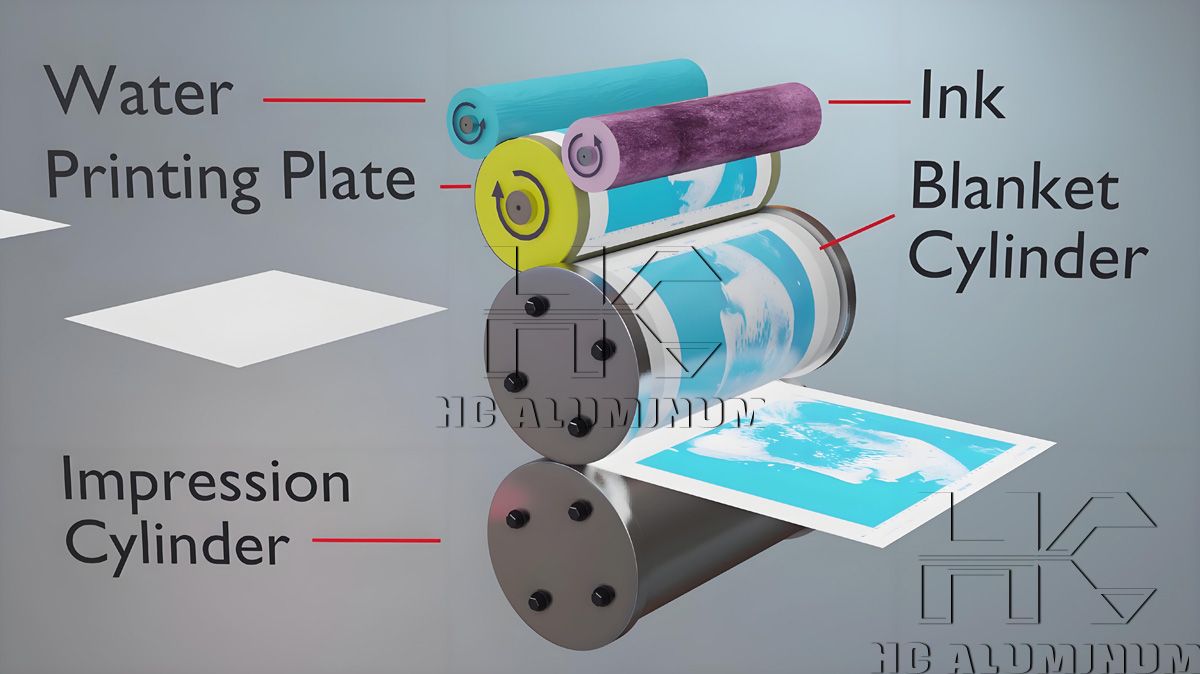

In daily life, newspapers, magazines, and most paper packaging boxes are produced through offset printing. The first step in offset printing is plate-making. After preparing the digital file of the image to be printed, it can be directly output to the plate using a Computer-to-Plate (CTP) machine, and the aluminum plate used is called a CTP plate.

A thermal CTP plate is an offset plate made using thermal imaging technology. It does not have a photosensitive layer but forms an image by heat exposure in the infrared wavelength range of 800–1100 nm. Compared with violet laser CTP plates, thermal plates offer higher exposure precision, more stable imaging characteristics, and broader environmental adaptability, making them the preferred choice for commercial printing, packaging printing, newspaper printing, and label printing.

Structure of Thermal CTP Plates

Base Aluminum Sheet

High-quality 1050 or 1060 aluminum alloy substrates are used, with surfaces treated by anodizing and electrochemical roughening. This ensures strong adhesion between the thermal coating and the aluminum base while providing high durability and excellent dot reproduction, guaranteeing high-quality printing results.Anodized Layer

Provides excellent hydrophilicity and corrosion resistance, ensuring stable ink transfer during printing.Photosensitive Coating

Made of thermal polymer materials, highly sensitive to 830 nm infrared lasers, with fast response and sharp imaging edges.Protective Layer

Prevents moisture or contamination of the coating, improving storage and transport stability.

Technical Specifications of Thermal CTP Plates

| Photosensitive Wavelength | 830 nm infrared thermal |

| Exposure Energy | approx. 110-120 mJ/cm² |

| Safe Handling Light | daylight processing possible |

| Compatible Equipment | Various thermal CTP output machines |

| Resolution | 2400-2800 dpi |

| Screen Ruling | 1-99% @ 200 lpi |

| Development Type | Specialized thermal developer / processless development |

| Print Run | ≥100,000 impressions (standard), ≥300,000 impressions (baked) |

| Storage Conditions | 10-30°C, 30-70% RH, keep sealed and away from light |

| Available Thickness | 0.15 mm / 0.20 mm / 0.25 mm / 0.30 mm |

| Development Conditions | Temperature 22-23°C, time 25-30 seconds |

| Available Sizes | Customizable to fit A3 up to full-sheet CTP machines |

Why Thermal CTP Plates Are the Industry Preferred Choice

1. Ease of Operation: Thermal CTP uses infrared laser to form images through heat. Plates can be safely handled under normal indoor lighting for up to 1 hour, or under yellow light for 12 hours, greatly improving convenience and safety.

2. High-Resolution Imaging: Thermal plates offer resolutions up to 2400–2800 dpi, precise screen ruling, and sharp dot edges, suitable for high-precision commercial and high-quality packaging printing.

3. Excellent Print Compatibility: Dots are solid and edges are sharp, ensuring stable ink-water balance during printing and precise dot control. Dot reproduction ranges 1-99% @ 250 lpi, meeting high-quality printing requirements.

4. High Print Endurance: Unbaked thermal plates achieve 150,000–200,000 impressions, and baked plates can reach over 1,000,000 impressions, suitable even for coated paper and UV ink printing.

5. Environmental and Economic Benefits: Thermal CTP plates can be processless, reducing chemical usage and environmental impact. Compared to traditional PS plates, they require less ink for the same printing results, saving ink costs.

6. High Cost-Effectiveness: Thermal CTP plates are highly efficient, with low waste rates and long lifespan, effectively lowering prepress costs, making them ideal for medium and large printing operations.

Applications

Thermal CTP plates are widely used across various printing sectors, particularly suitable for:

High-Quality Commercial Printing: Brochures, magazines, advertisements requiring high dot reproduction.

Long-Run Printing: High endurance makes them ideal for large-volume print jobs.

Spot Color Printing: Sharp dot edges and excellent ink transfer performance.

UV Printing: Good compatibility with UV inks.