Welcome to HongChang Aluminum CO., LTD.

Visit

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Welcome to HongChang Aluminum CO., LTD.

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

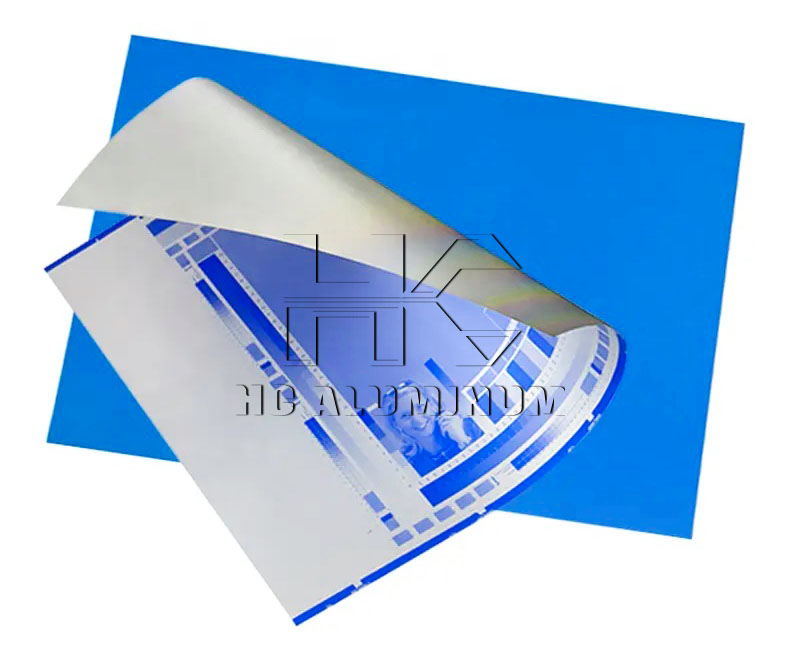

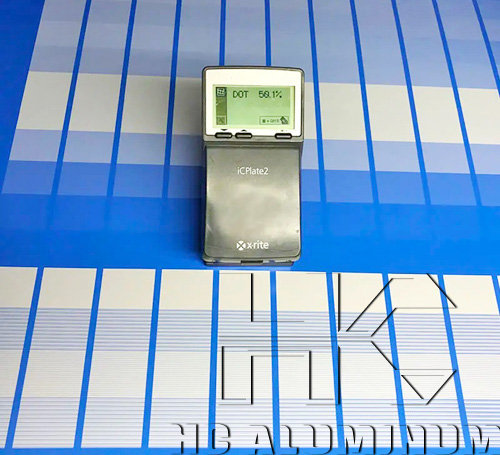

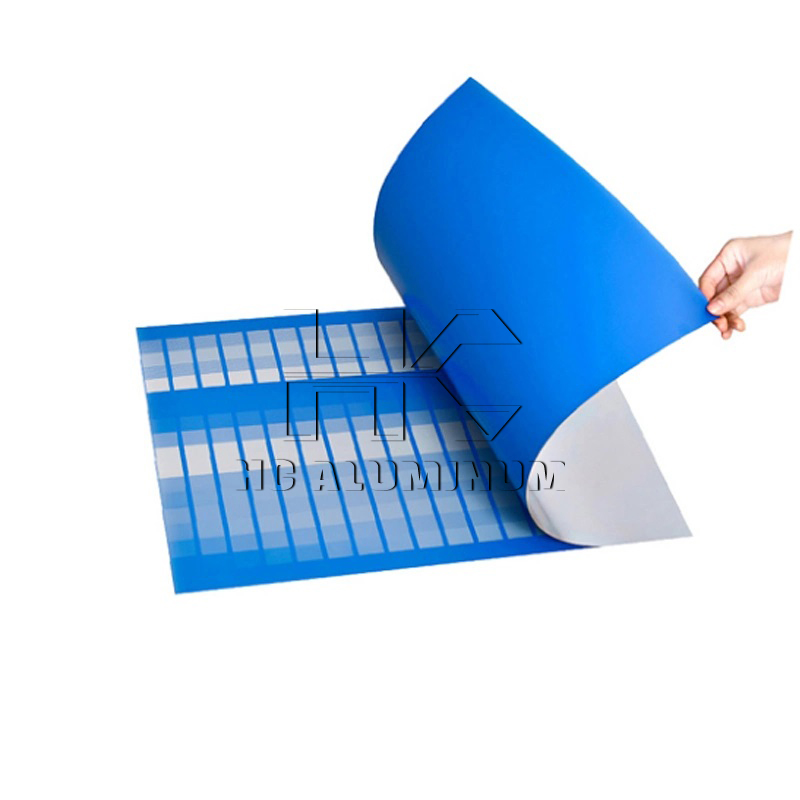

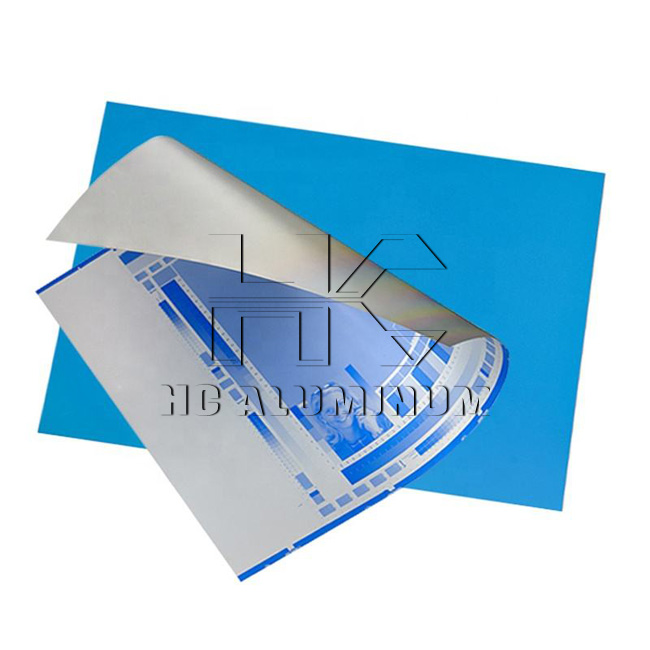

PS/CTP are both rolled into a certain thickness of thin plate through hot and cold rolling process. The surface of the plate is coated with a layer of photosensitive resin after a specific process treatment, and then dried to make a printing plate for var

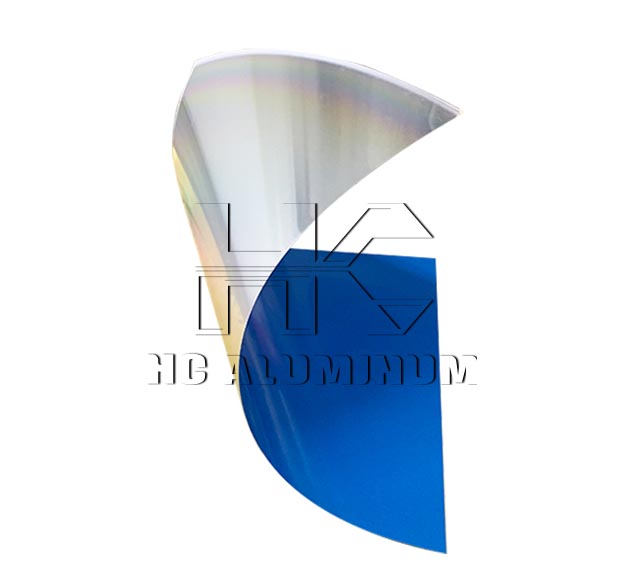

Processless thermal CTP plates use 830 nm thermal imaging technology and require no chemical development, offering high plate-making efficiency and excellent stability, making them ideal for high-volume commercial and packaging printing applications.

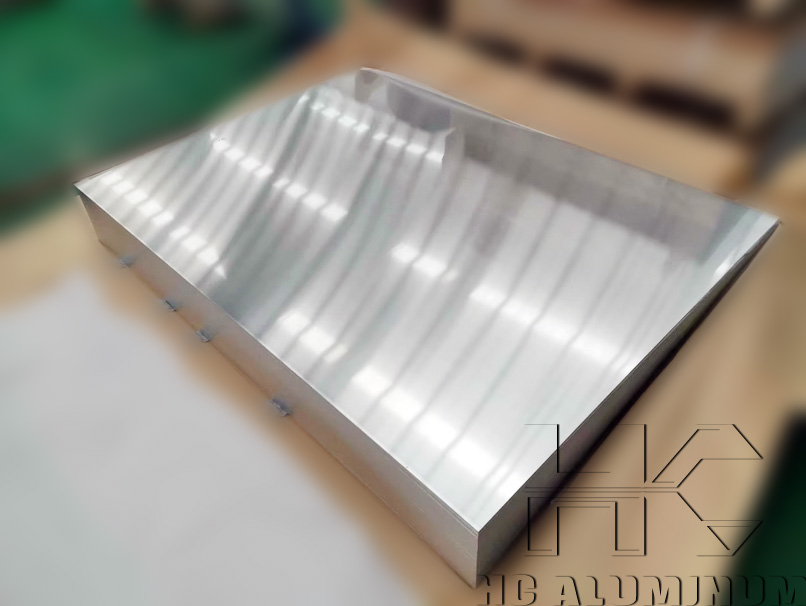

1050A aluminum sheet is a high-purity aluminum alloy material with an aluminum content of about 99.5%, similar to 1050 aluminum sheet, but with slightly higher purity and more stable performance.

Thermal CTP plates are one of the core plate materials used with mainstream printing presses, offering high efficiency, high stability, and high resolution.

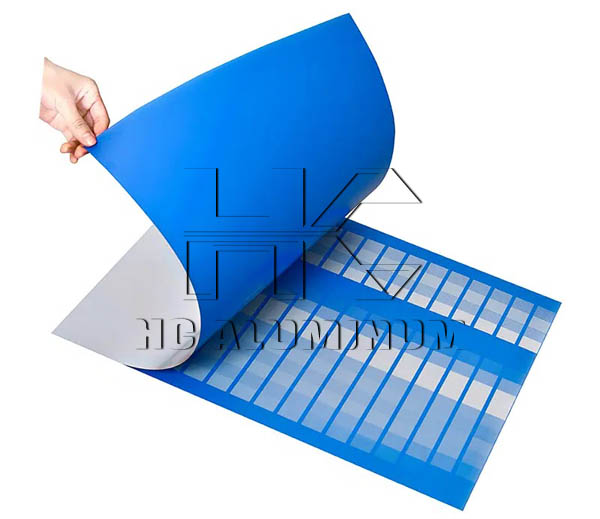

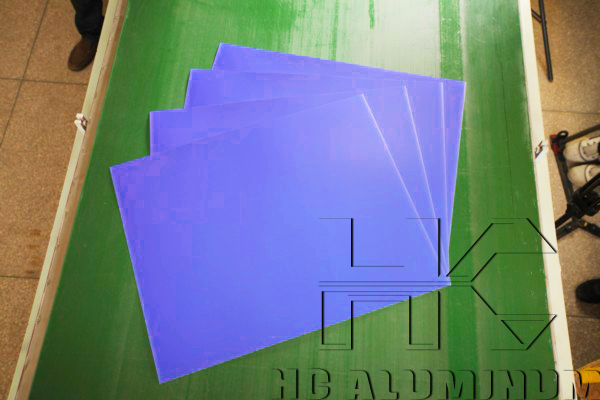

Thermal CTP plates are commonly available in thicknesses of 0.15mm, 0.20mm, 0.25mm, and 0.30mm. They use thermal technology and are imaged by an 830nm infrared laser, requiring no chemical development, making them suitable for commercial printing applicat

CTP plates primarily use aluminum plates, which not only improves printing efficiency but also reduces plate-making costs.

In the printing industry, PS sheet (pre-coated photosensitive sheet) refers to a sheet made by coating a non-silver photosensitive (thermal) resin layer on an aluminum substrate sheet. For photosensitive sheet substrates, 1050, 1060, 1070, 1050A aluminum

Hot-rolled 1100 CTP aluminum sheet belongs to the pure aluminum sheet series, with relatively low strength, but excellent ductility, formability, weldability and corrosion resistance;

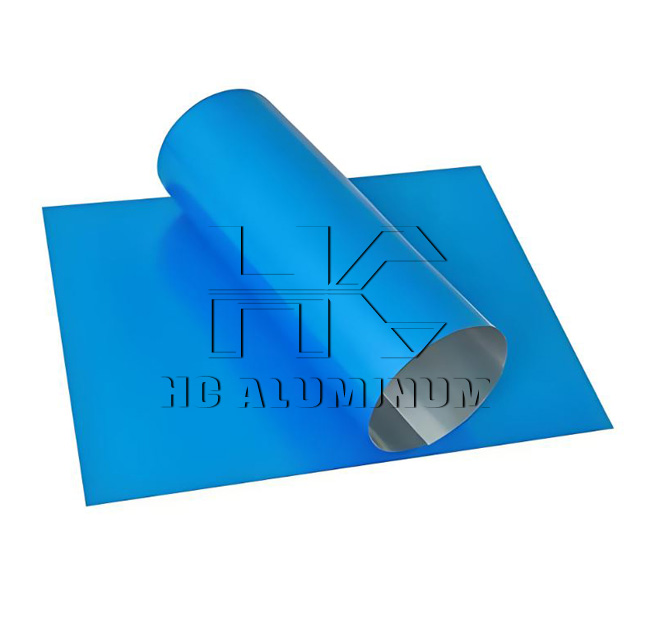

Aluminum PS plates are the core consumables of offset printing presses. The base material is primarily 1050, 1060, or 1070 aluminum alloy. The surface is electrolytically oxidized to create a grain structure and then coated with a photosensitive resin.

The substrate of printed PS aluminum plate is generally 1 series 1060-H18 aluminum coil alloy. In addition to being used to make PS plates for printing, 1060 aluminum coil is also widely used in offset printing plates such as positive PS plates, thermal C

The core advantages of 830 nm thermal CTP plates lie in their operational stability and the convenience of working in a brightly lit environment.

Aluminum coils for CTP/PS base plates are mostly made of high-purity aluminum alloys, such as 1050, 1060, 1100, etc. The aluminum content of these alloys is ≥99.50%, ≥99.60% and ≥99.00%, respectively. They have the advantages of high purity, low density,

CTP aluminum substrate made of 1050, 1060, 1070 aluminum sheets, these aluminum alloys are known for their high purity and good processing performance. 1 series aluminum plate can provide good conductivity, ductility and corrosion resistance, suitable for

CTP aluminum plate base is a material used in the printing industry. It is a printing platemaking technology that directly transfers the numbers, pictures or pages edited in the electronic prepress processing system or color desktop system to the printing

1-Series photopolymer plate aluminum substrates are made from 1050, 1050A, 1060, and 1070 aluminum sheets as the supporting material for photopolymer plates (such as PS plates and CTP plates).

1 series aluminum alloy plates are commonly used for PS plate substrate/CTP plate substrate, with advantages such as high printing quality, strong printing durability, environmental friendliness, cleanliness and hygiene, and low cost.

Keyword,Search Intentbest thermal CTP plates for long run offset printing,Commercialwholesale price per square meter CTP plate for offset,TransactionalUV CTP plates vs thermal CTP plates comparison for offset,Investigational830nm thermal CTP plate manufac

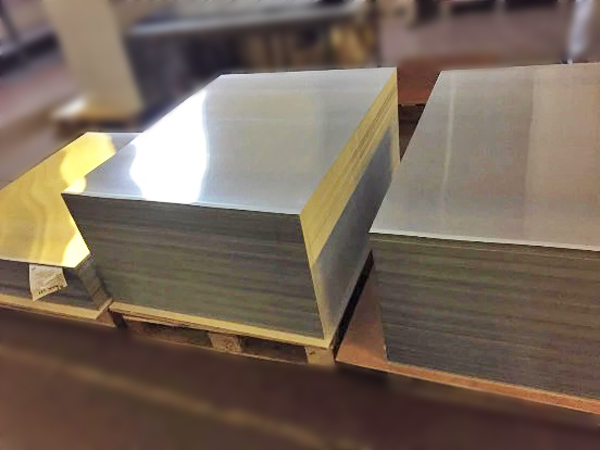

With the vigorous development of the printing industry, the demand for printing plates has shown a significant growth trend. Among them, the demand for PS plates/CTP plates, which are the main printing plates, is particularly prominent. The PS version of

CTP sheets have the advantages of high printing quality, no environmental pollution, remote sheet making, and on-demand printing. Therefore, the application of CTP sheets has been rapidly developed and has become a trend to replace traditional PS sheets.

MC Aluminum is a manufacturer specializing in the production of 1060-h18 aluminum sheets for printing platemaking. The thickness range of production is between 0.13-0.40mm, and it can be customized.

High sensitivity positive thermal CTP plates with excellent dot reproduction, stable imaging performance, and wide exposure latitude.Suitable for commercial and packaging offset printing.

Thermal CTP plates use an infrared thermal laser around 830nm to create images directly on aluminum-coated plates, eliminating the need for traditional film transfer processes.

Blue Thermal CTP Printing Plates designed for 830nm thermal imaging deliver high resolution, stable dot reproduction, and long run length. Compatible with mainstream CTP systems, suitable for commercial, packaging, and newspaper printing applications.

A thermal CTP plate is an aluminum-based printing plate coated with a thermally sensitive imaging layer. It is imaged by an 830 nm thermal laser CTP setter without the use of film, significantly improving prepress efficiency.

Ctcp plate is a computer-generated plate made directly on a traditional plate, replacing the traditional film platemaking method. The positive Ctcp plate inherits the advantages of CTP such as timeliness and high quality, a

The alloys used for aluminum base sheet production in CTP sheet production are usually 1050, 1060 aluminum coil, etc. Aluminum coil is usually highly processed aluminum, and the surface is anodized to improve corrosion resistance and prepare for subsequen